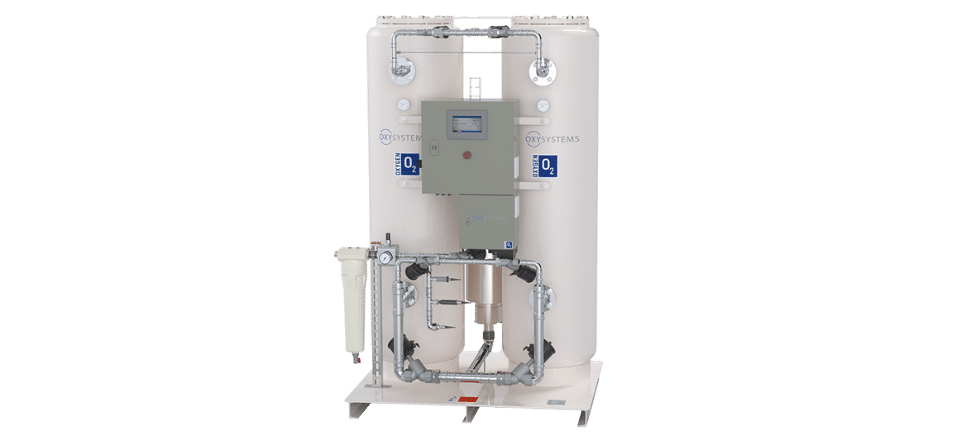

Nitrogen generator OxySystems

Oxysystems

Industrial nitrogen generators, PSA technology

Produce your own nitrogen directly on-site with OxySystems generators, delivering a continuous and cost-efficient nitrogen supply with adjustable purity levels up to 99.999%. The ideal solution for pharmaceutical, food and beverage, and biotechnological industries.

Advantages

Advanced PSA or membrane technology for optimal purity and stability

Adjustable nitrogen purity: from 95% to 99.999%

Flow rates ranging from a few liters to several hundred Nm³/h

Continuous and fully autonomous nitrogen production on-site

Low operating costs and minimal maintenance

Compact, modular system suitable for fixed or mobile installations

Fully automated control system with remote monitoring option

Energy-efficient and environmentally friendly operation

Plug & play integration into existing production processes

OxySystems nitrogen generators provide a sustainable and economical alternative to traditional nitrogen cylinder or liquid nitrogen deliveries.

Using PSA (Pressure Swing Adsorption) or membrane technology, they allow continuous, on-demand nitrogen generation with purity levels ranging from 95% to 99.999%, depending on application needs.

Designed for both small-scale and large industrial operations, these systems guarantee autonomous, safe, and uninterrupted nitrogen supply, independent of external environmental or temperature conditions.

Their compact and modular design enables easy installation, whether as a mobile or stationary production unit, ensuring maximum flexibility and efficiency.

| Parameter | Value / Range |

|---|---|

| Technology | PSA or Membrane |

| Nitrogen purity | 95% to 99.999% |

| Flow rate | 1 to 500 Nm³/h (depending on model) |

| Outlet pressure | 5 to 10 bar |

| Operating temperature | 5°C to 45°C |

| Noise level | < 65 dB |

| Power supply | 230/400V – 50Hz |

| Installation type | Fixed or mobile |

| Control system | PLC with touchscreen / Remote monitoring |

| Maintenance | Low – automatic regeneration cycles |

Blister filling:

Use nitrogen to fill blisters in order to extend the shelf life of pharmaceutical products.Capsule filling:

Use nitrogen during capsule filling to increase the stability and lifespan of active ingredients.Chemical storage:

Nitrogen is used to create an inert atmosphere for the safe storage of chemical products.