Dynamic weight sorting

Dynamic weight sorting systems are essential for automated quality control in manufacturing, food processing, and logistics industries. By continuously measuring the weight of products in real time, these systems ensure accurate sorting, grading, and compliance with weight regulations, reducing waste and improving efficiency.

* By filling out the form, I accept the use of my personal data for professional purposes. Learn more about our Privacy policy

Documentation & Publications

-

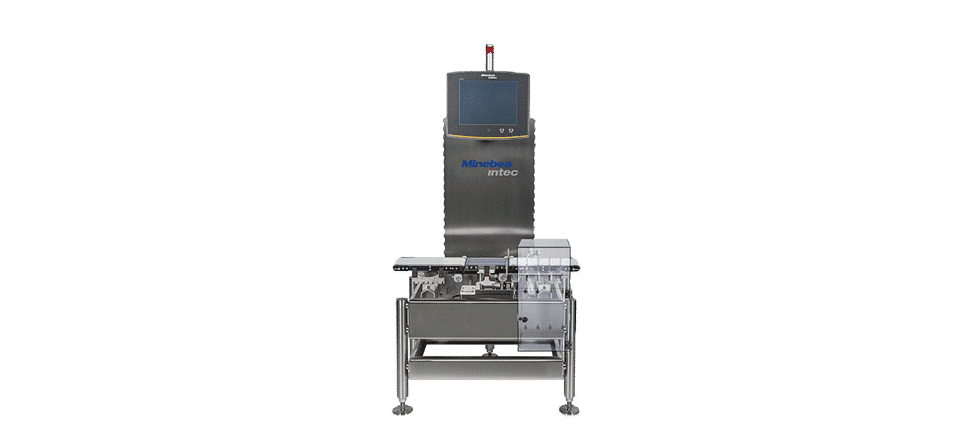

FLEXUS Checkweighers

The FLEXUS Checkweighers by MINEBEA INTEC provide a high-precision solution for weight checking, ensuring efficient and accurate product sorting to maintain the quality and compliance of your production line. -

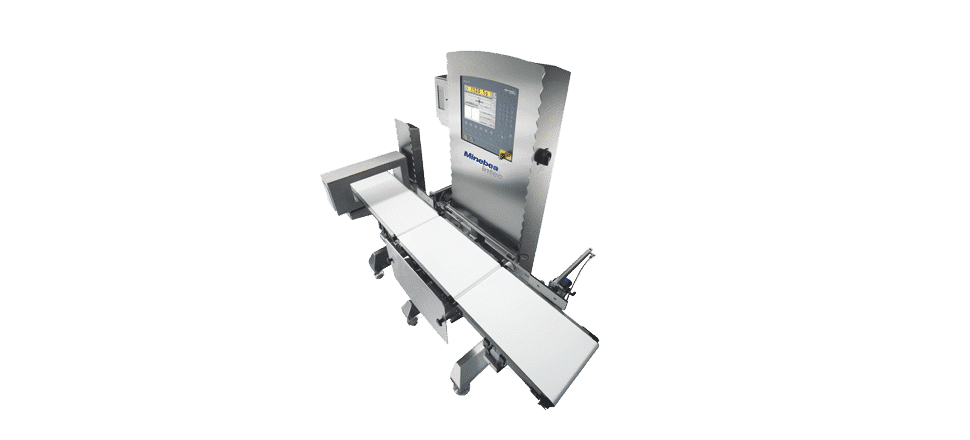

ESSENTUS Checkweighers

The ESSENTUS Checkweighers by MINEBEA INTEC offer a high-precision solution for weight checking, ensuring efficient and accurate product sorting to uphold the quality and compliance of your production line. -

SYNUS Checkweighers

The SYNUS Checkweighers by MINEBEA INTEC provide an advanced solution for high-precision weight checking, ensuring accurate and efficient product sorting to maintain the quality and compliance of your production line.

Modern dynamic weight sorters integrate high-speed sensors, precision conveyors, and advanced software for real-time analysis and automatic decision-making. They enhance production line performance, minimize manual intervention, and support regulatory compliance. By implementing dynamic weight sorting technology, organizations achieve higher product quality, improved operational efficiency, and reliable traceability across production processes.