Petrol quality control

Petrol quality control is a critical process in the fuel industry, ensuring that gasoline meets stringent performance, safety, and environmental standards. By analyzing properties such as octane rating, sulfur content, volatility, and contaminant levels, quality control helps maintain engine efficiency, reduce emissions, and comply with regulatory requirements. Accurate testing ensures that fuel is safe, reliable, and consistent for consumer and industrial use.

* By filling out the form, I accept the use of my personal data for professional purposes. Learn more about our Privacy policy

Documentation & Publications

-

GC Intura N2 Gas Generators

The Intura N2 range from Peak Scientific models 250, 600, and 1000 offers GC & GC-MS laboratories an ultra-pure nitrogen solution and constant, with flow rates adapted to different needs. -

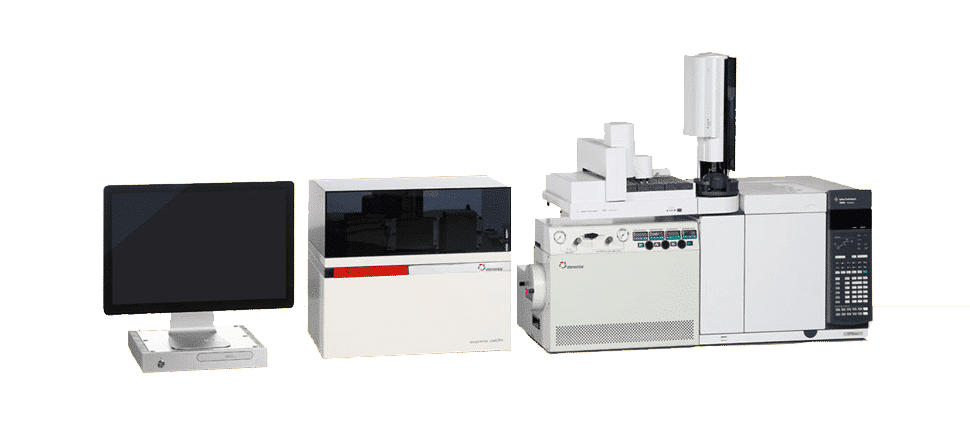

EMA 502 Elemental Analyzer CHNS-O

Precise, versatile, cloud-enabled micro elemental analyzer for Carbon, Hydrogen, Nitrogen, Sulfur and Oxygen determination with Helium and Argon as carrier gas. -

Tube reader DR10

A new instrumental method of quantitative measurement of tube deposits has been developed by AD Systems, in which the thickness of the deposit is accurately determined by an automatic instrument, reducing test subjectivity.

-

PetrovisION

An Elementar experience where the user is free from the routine chores of maintenance allowing them to focus on the science, not the instrumentation. -

KV6 Viscometer Bath

The Seta KV-6 gives the user a high quality and robust solution for kinematic viscosity determinations.

-

AKV-202 Viscosity Measuring System

Model AKV-202 has been designed for automatic determination of Kinematic Viscosity.

-

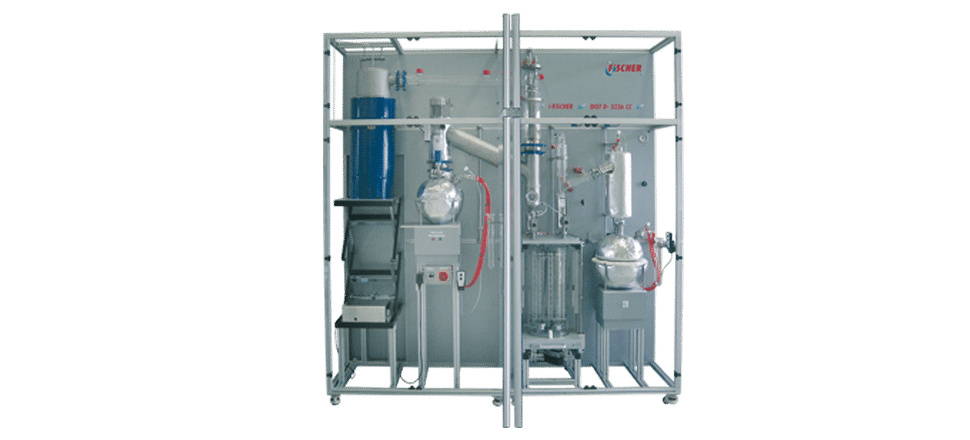

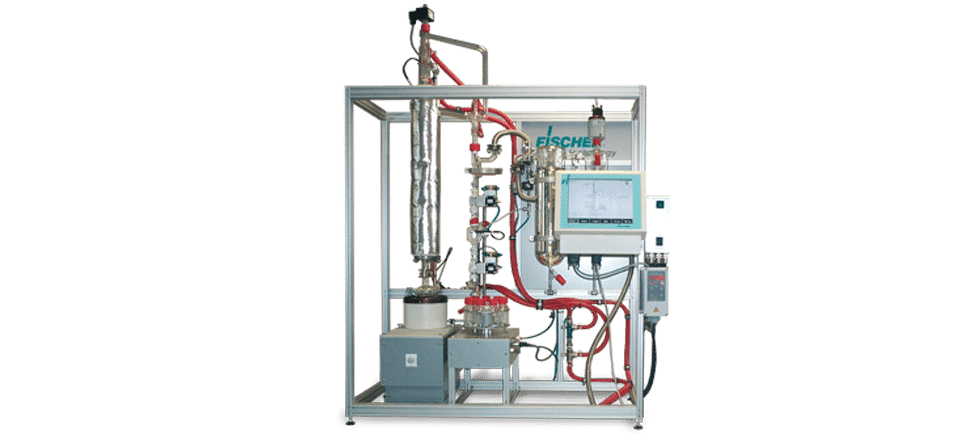

Distillation TBP Automatic ASTM D2892

The i-Fischer® DIST D-2892 CC / FISCHER® AUTODEST® 800 AC is a fully computer controlled unit of turn-key design, and ready for use after installation and commissioning.

-

Distillation TBP Semi-automatic ASTM D2892

The i-Fischer® DIST D-2892 MC / FISCHER® AUTODEST® 800 MC is a computer controlled unit of turn-key design, and ready for use after installation and commissioning.

-

Distillation Potstill automatic ASTM D5236

The i-Fischer® DIST D-5236 CC / FISCHER® AUTODEST® 860 system is fully equipped, turnkey, and operational as soon as installation and commissioning is complete.

-

Distillation Potstill semi-automatic ASTM D5236

The i-Fischer® DIST D-5236 ™ / FISCHER® AUTODEST® 860 ™ is a computerized, turnkey, and operational unit from the end of installation and commissioning.

-

Distillation Potstill HV ASTM D5236

The i-Fischer® DIST D-5236 CC / FISCHER® AUTODEST® 860 AC can be converted to the “HV”-version by adding an extended Potstill-column to the standard ASTM-system (Potstill).

-

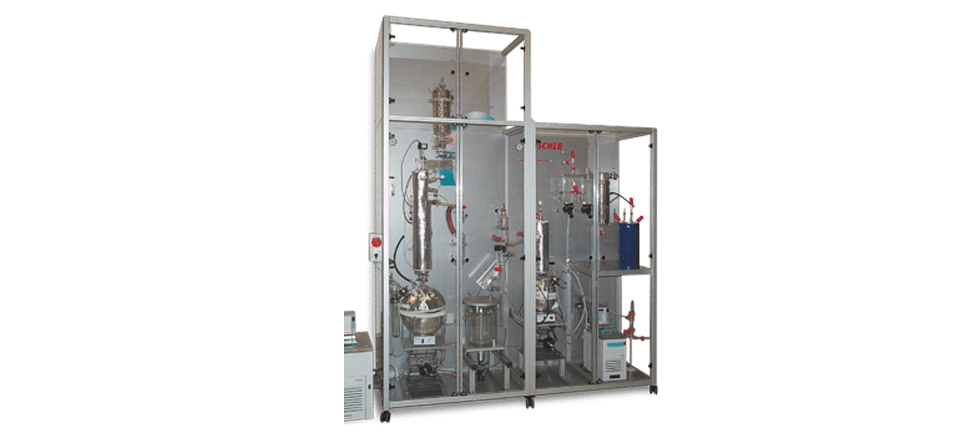

Distillation CC automatic ASTM D1160

The i-Fischer® DIST D-1160 CC / FISCHER® AUTODEST® 850 AC is a fully computer controlled unit of turn-key design, and ready for use after installation and commissioning.

-

Distillation combined automatic ASTM D2892 / D5236

The i-Fischer® DIST D-2892/5236 CC / FISCHER® AUTODEST® 800/860 AC is a fully computer controlled unit of turn-key design, and ready for use after installation and commissioning.

-

Distillation Combined semi-automatic ASTM D2892 / D5236

The i-Fischer® DIST D-2892/5236 MC / FISCHER® AUTODEST® 800/860 MC is an automated, computer controlled and PC operated unit of turn-key design, and ready for use after installation and commissioning.

-

Micro-distillation

Compact and especially versatile, the fully automated FISCHER® LABODEST® HMS 500 AC is a unit with highest separation efficiency.

HTDS provides comprehensive petrol quality control solutions, including advanced analytical instruments, monitoring systems, and testing consumables. These technologies deliver precise measurements, rapid analysis, and reliable results, enabling professionals to optimize production processes and maintain high-quality fuel standards. With HTDS solutions, fuel manufacturers and laboratories can ensure product safety, regulatory compliance, and operational efficiency across all stages of petrol production and distribution.