Sulfer Content

Sulfur content analysis is a critical process in fuel, petrochemical, and industrial applications, ensuring that sulfur levels are accurately measured and controlled. Precise determination of sulfur content helps prevent corrosion, reduce emissions, comply with environmental regulations, and maintain product quality. This analysis is essential for refining processes, quality assurance, and regulatory compliance across a wide range of materials and products.

* By filling out the form, I accept the use of my personal data for professional purposes. Learn more about our Privacy policy

-

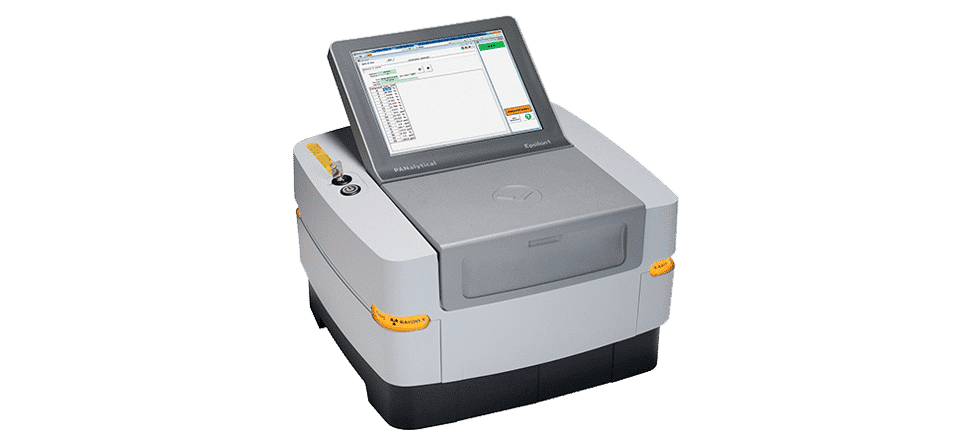

Epsilon 4 Lubricating oils

For the Epsilon 4 the mandated compliancy is merely the starting point ; where the instrument really shines is the additional value it brings for many other analytical tasks in the production of lubricating oils

-

Epsilon 4 Oils & fuels

Compliant, repeatable and accurate elemental analysis is a given but additional value is generated in several parts in your refining operation

-

Epsilon 1 Sulfur in fuels

Epsilon 1 is the ideal analytical solution. The system is pre-calibrated in the factory and is an out-of-the-box solution with guaranteed performance in compliance with ASTM D4294, ISO 20847, ISO 8754, IP496, IP336 and JIS K2541-4.

-

Epsilon 1 Lubricating oils

The system is pre-calibrated in the factory and is an out-of the-box solution with guaranteed performance in compliance with ASTM D6481. This method describes the testing for phosphorus, sulfur, calcium and zinc in unused lubricating oil by XRF.

-

H2S Analyser

The instrument offer rapid and accurate measurement of H2S in petroleum products

descriptions

HTDS provides advanced sulfur content analyzers that deliver high precision, reliability, and ease of use. Designed for both laboratory and on-site applications, these instruments offer fast, accurate measurements and robust performance under diverse conditions. With HTDS solutions, professionals can optimize process control, ensure compliance with strict standards, and maintain high-quality outcomes in all sulfur-sensitive operations.