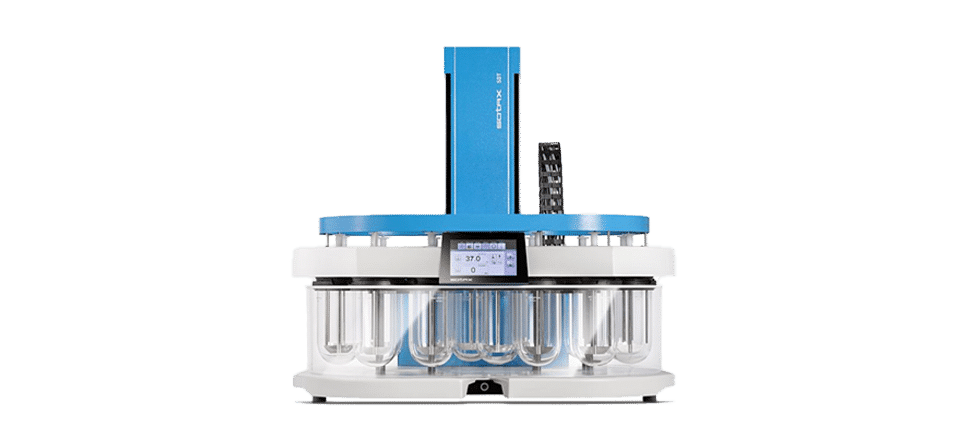

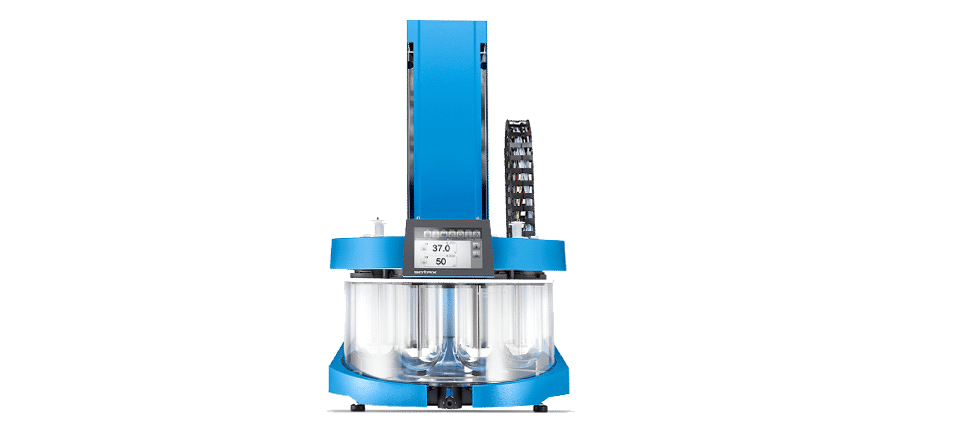

Disintegration testing

Disintegration testing is a critical quality control procedure used to evaluate the time it takes for solid dosage forms, such as tablets or capsules, to break down into smaller particles under standardized conditions. This test is widely applied in the pharmaceutical industry to ensure proper drug release, bioavailability, and compliance with regulatory requirements. Accurate disintegration testing ensures that medications perform as intended and meet strict quality standards.

* By filling out the form, I accept the use of my personal data for professional purposes. Learn more about our Privacy policy

-

SDT-L Manual

The SDT-L manual is a robust and cost-effective solution for USP-compliant dissolution testing.

-

MPS Media Preparation Station

The MPS Media Preparator is a versatile solution that meets the needs of pharmaceutical and biotechnology laboratories for dissolution media preparation.

-

MP Xtend Preparator

The MP Xtend Preparator is a versatile and robust solution for the automated preparation of dissolution media.

-

Dissolution Testing USP 1/2/5/6 AT Xtend

Xtend™ allows flexible automation of your dissolution processes. Changing testing requirements? Standardized Xtend™ modules can be combined to differently automated dissolution systems - making method transfer and scale-up easier than ever. From manual baths to fully automated dissolution systems with multiple networked systems, Xtend™ is one platform for all your dissolution needs.

-

Flow-through Dissolution USP 4

Dissolution in continuous flowClosed loop or open system mode Achoice of cell adapted to each gamenic form

descriptions

HTDS offers advanced disintegration testing systems designed for precision, reliability, and ease of use. Equipped with automated testing mechanisms, temperature-controlled baths, and intuitive software, these systems deliver fast, reproducible, and accurate results. With HTDS technologies, professionals can optimize pharmaceutical quality control, ensure product consistency, and maintain high standards of safety and efficacy in laboratory and production environments.