Hardness testing

Hardness testing is a fundamental method for evaluating the mechanical properties of materials, including metals, polymers, and coatings. By measuring resistance to deformation and surface strength, these tests provide critical insights for quality control, material selection, and product performance in industrial applications.

* By filling out the form, I accept the use of my personal data for professional purposes. Learn more about our Privacy policy

-

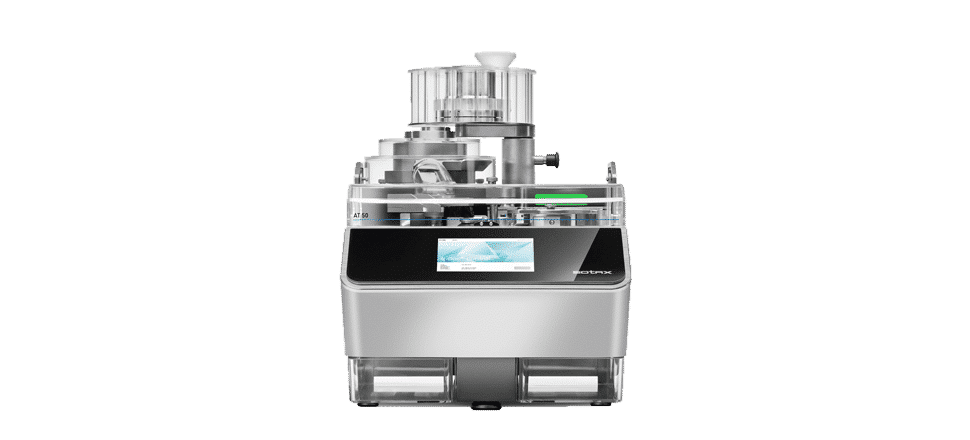

Hardness Tester AT50

The AT50 is an ideal instrument for both laboratory automation and online testing with your tablet press. It ensures comparability of results throughout IPC, QC and R&D.

-

TM 200

The TM 200 is a torque-measuring device specially designed to work on bottle caps.

-

Tap density tester TD1

Turnkey solution for your testing compaction of powders according to USP or EP

-

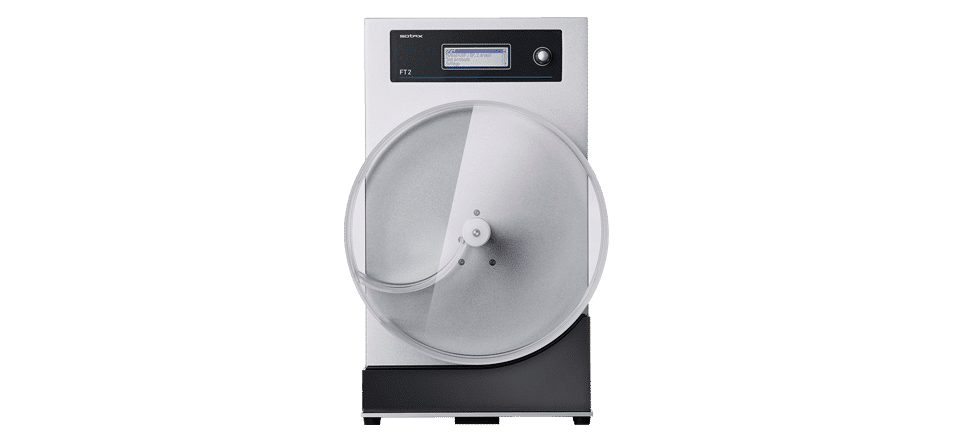

Friability tester FT2

Measure the friability or abrasion of the tablets, whatever their size, with the ease of emptying.

-

Smart Test 50

The SmartTest 50 is capable of testing virtually all tablet shapes and can easily be programmed to meet your individual testing requirements.

-

Disi Test 50

Using state-of-the-art induction heating technology, the test medium quickly reaches the required temperature within 3-5 minutes reducing unproductive waiting times to a minimum.

-

Disintegration tester DT2

Thanks to its two independent positions or supportive, accepting baskets A and B, it adapts to any type of medication, and is upgradeable to automatic detection

descriptions

Modern hardness testing systems integrate precision instruments, automated measurement protocols, and data analysis software for accurate and reproducible results. Widely used in manufacturing, engineering, construction, and research, they help organizations enhance product durability, ensure compliance with industry standards, and optimize material performance.